A intriguing component that frequently goes unseen but is essential to the seemingly mystical phenomenon of wireless power transfer is the air core inductor. This amazing technology uses electromagnetic energy to carry electrical energy through the air, circumventing the requirement for physical connections. In the blog below, we set out on an adventure through the world of air core inductors, learning about their inner workings, uses, and the astounding idea of wireless charging.

The air core inductor consists of a coil of wire wound around a plastic or ceramic non-magnetic core. The distinguishing characteristic of air core inductors, which distinguishes them from their iron or ferrite core equivalents, is the lack of a magnetic core. But how does this apparently straightforward mechanism make it possible to transmit energy via the air?

Electromagnetic Induction

The principles of electromagnetic induction, a phenomena identified by the great Michael Faraday in the 19th century, are at the foundation of the magic of air core inductors. Faraday's law states that as an electric current passes through a wire, a magnetic field is created all around it. On the other hand, when a magnetic field crosses a loop of wires, it causes an electric current to flow through the loop. The foundation for wireless power transfer utilizing air core inductors is this fundamental idea, and this is how it works.

- A power source, such as an electrical outlet, is connected to an air core inductor coil on the transmitting side of the wireless charging system. This coil produces a magnetic field around it when an electric current runs through it.

- The receiving apparatus, which is furnished with a second air core inductor coil, is positioned close to the transmitting coil. The transmitting coil's fluctuating magnetic field causes the receiving coil's electric current to flow.

- This induced current in the receiving coil is then transformed back into electrical energy, which can be utilized to power the device or recharge a battery.

In air core inductors, the lack of a magnetic core enables effective transmission of magnetic fields and, subsequently, electrical energy via the air. The foundation of many applications, including wireless charging pads for cell phones, electric toothbrushes, and even electric vehicle charging systems, is the wireless power transmission principle.

Additional uses besides wireless charging

Although one of the most well-known uses for air core inductors is wireless charging, they have other uses as well. Here are a few more applications for air core inductors.

- RFID Technology: Air core inductors are used in tags and readers for radio-frequency identification (RFID) systems. These inductors are essential to the operation of RFID tags, which are utilized in applications including contactless payments, inventory management, and access control.

- Wireless communication: Air core inductors are used in wireless communication systems, such as RF transmitters and receivers, to transmit and receive data wirelessly. They are an essential component of gadgets like walkie-talkies, remote controls, and Wi-Fi routers because they aid in the transmission and receiving of radio signals.

- Antennas: Air core inductors are used to build antennas for many different purposes, such as radio transmission, cellular communication, and satellite communication. They aid in fine-tuning antennas to certain frequencies for the best signal transmission and reception.

The Future Of Air Core Inductors

The importance of air core inductors in enabling wireless power transfer and wireless communication will only increase as technology develops. The effectiveness and reach of wireless charging systems are likely to be significantly enhanced by developments in materials and design, making them a crucial component of our increasingly linked world. Air core inductors are undoubtedly the unsung heroes of contemporary technology, whether it is for facilitating flawless data transmission or charging your smartphone wirelessly.

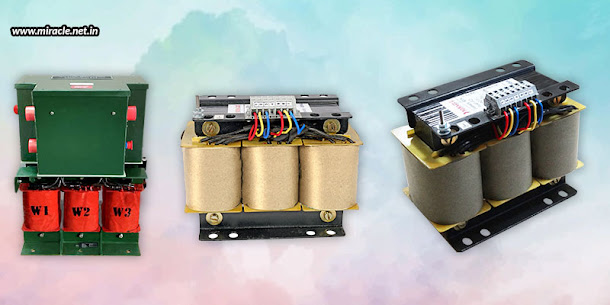

Miracle Electronics is one of the most well-known air core inductor manufacturers in India, where you can get the finest products, all certified for Genuity and compliance to standards.