Transformers being responsible for moving power between circuits quietly and effectively, industry leaders and researchers are now prioritizing maintaining their efficiency. Improving transformer efficiency lowers energy losses while also saving money and contributing to sustainability. This article examines the complex problem of increasing transformer efficiency and the creative solutions being proposed.

The pursuit of increased productivity

The efficiency of a transformer is important for a number of reasons, such as lowering operating costs, minimizing environmental effect, and eliminating energy waste. Transformers do, however, have a number of difficulties that affect their effectiveness. These are a few of the main challenges –

- Core losses: Hysteresis and eddy currents can cause energy losses in the core materials of transformers, which decreases the efficiency.

- Heat dissipation: Overheating can cause the transformer to become inefficient and damaged.

- Voltage regulation: Efficiency depends on the ability to maintain a constant output voltage even in the face of fluctuating loads and input voltages.

- Environmental impact: Efficiency and the environment may be impacted by the insulating fluid selection, such as conventional mineral oil.

- Ageing infrastructure: A large number of transformers still in operation today may not be as efficient as they should be. Upgrading or replacing them is a significant challenge.

Strategies to Increase Productivity

It will take a combination of cutting-edge technologies and solutions to solve the aforementioned issues. The following tactics have been devised to enhance transformer efficiency.

- Advanced core materials: Core losses can be considerably decreased by using advanced core materials, such as amorphous metals or nanocrystalline alloys. These materials are more efficient because they have less hysteresis and eddy current losses.

- Smart cooling systems: Modern cooling technologies, such directed-flow fans and more effective cooling fluids, can aid in the more efficient dissipation of heat. Maintaining efficiency and avoiding overheating require effective cooling.

- Digital monitoring and maintenance: Proactive maintenance is made possible by real-time transformer monitoring. By minimizing unplanned downtime, predictive maintenance keeps the transformer running as efficiently as possible.

- Load management: Improving transformer loads and making sure they run within their designated range can both lead to increased efficiency. Load management improves the system’s overall efficiency and reduces energy losses.

- Voltage regulation: One of the most important factors in transformer efficiency is voltage regulation. On-load tap changers (OLTCs) and voltage regulators are examples of sophisticated voltage control devices that can guarantee steady output voltage under a range of loads and input voltages. Efficiency gains are partly attributable to this stability.

- Load-tap changing transformers: These transformers enable voltage regulation under a range of load circumstances by adjusting the turns ratio. More effective operation can be achieved through proper load-tap changing, particularly in situations where loads fluctuate.

- Compact designs: By lowering copper losses, smaller, more compact transformers with better insulation materials can shorten conductor lengths and increase overall efficiency. Compact designs are very useful in confined urban spaces.

- Eco-friendly insulating fluids: Transformers can be made more efficient and have a smaller negative impact on the environment by using natural ester-based oils in place of conventional mineral oil. These fluids have improved fire resistance and heat dissipation.

- Smart grid integration: Real-time control and communication are made possible by the incorporation of transformers into smart grids. Smart grids reduce energy losses by optimising their functioning for efficiency and load management.

- Lifecycle cost analysis: Making well-informed judgements concerning transformer selection and operation can be aided by taking into account the total cost of ownership over a transformer’s full lifecycle, including efficiency and maintenance expenses.

Enhancing transformer efficiency is essential for contemporary electrical systems. Although there are significant challenges, there is a way forward using the techniques mentioned above. We may expect even more creative ideas and a greater emphasis on efficiency as technology develops. We are getting closer to a future in the transformer industry where sustainability is valued, expenses are minimized, and energy conservation is achieved. This is not just about making transformers better, but about creating a more responsible and efficient power distribution system for the future.

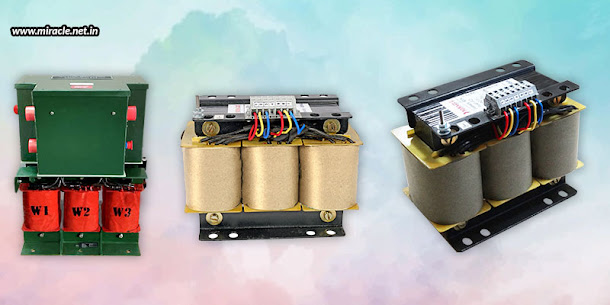

While we move into the future slow and steady, when you’re looking for efficient transformers in the present, you can always approach reputable transformer suppliers in India, one like Miracle Electronics, where you are guarantees to receive only authentic products and high quality transformers that comply with RoHS and REACH, which ensures dependability and credibility at every step.