The sound quality of amplifiers is largely dependent on an audio output transformer India. Peak performance demands a sophisticated approach to design that takes core materials, winding methods, and impedance matching into account. Let's delve into these principles in detail for better understanding of the design concepts that go into creating high-grade audio output transformers, which in turn improve the sonic capabilities of amplification systems.

Core materials

The performance of audio output transformers is significantly influenced by the core material. Common materials bring different qualities to the table, such as nickel, ferrite, and laminated steel. The unique needs of the audio system determine the choice of core material, taking into account aspects like power management, frequency response, and cost. By adjusting for efficiency, frequency response, and saturation levels, designers may customize transformers for particular uses and enhance the overall performance of audio systems.

- Laminated steel cores stand out for their low core losses and remarkable magnetic characteristics. They are very efficient and versatile for a wide range of audio applications, making them widely favoured. But it's crucial to pay close attention to the thickness and quality of laminations. Thinner laminations are essential because they lower eddy current losses and boost total effectiveness. This highlights the significance of manufacturing process accuracy in ensuring that laminated steel cores satisfy the demanding specifications of audio systems, providing the best possible performance and reducing undesired losses in the conversion of electrical data to sound.

- Nickel cores are highly valued in audio output transformer applications and are perfect for high power needs because of their strong magnetic characteristics and high saturation levels, nickel cores. They are a favoured option in powerful audio settings due to their capacity to manage high power demands. Cost is a factor, though, as nickel cores can be somewhat more costly. For the purpose of controlling eddy current losses in particular, careful design is essential to minimising any negative effects. The benefits of strong magnetic characteristics and high saturation levels make nickel cores an attractive alternative for audio output transformer designs that require high power and efficiency, even with cost constraints.

- Ferrite cores are a very attractive alternative for audio output transformer construction because of their favourable high-frequency properties and lightweight nature. Ferrite cores help make audio systems more portable and small, making them especially well-suited for applications where weight and size are crucial factors. It's crucial to remember that ferrite cores might not be as suited for high-power applications as their nickel or steel equivalents because of their potential lower saturation levels. When choosing ferrite cores, it is important to carefully weigh the unique needs of the audio system in order to strike a balance between their benefits and drawbacks in terms of obtaining peak performance.

Winding techniques

An audio output transformer's primary and secondary coil winding precision is a crucial design factor. To reduce losses, improve coupling efficiency, and keep a flat frequency response, winding procedures must be applied carefully. An efficient power transmission between the coils is ensured by proper winding, which enhances the transformer's overall performance and fidelity. The dedication to minimizing resistive losses and optimizing the transformer's efficiency is demonstrated by meticulous attention to detail in obtaining precise winding processes, which provide a refined and accurate audio signal reproduction over the whole frequency spectrum.

- Layer winding and section winding selection in the construction of audio output transformers can have a significant impact on performance. Layer winding creates a better link between the primary and secondary coils for enhanced performance by winding each wire layer in a concentric manner. On the other hand, section winding separates the coil into parts and provides advantages like improved high-frequency response and decreased capacitance. Layer winding emphasizes overall coupling efficiency, while section winding addresses capacitance-related concerns. This design choice ultimately allows designers to customize transformers to achieve optimal performance characteristics based on the specific demands of the audio system.

- Uniform winding and insulation are integral aspects of audio output transformer design. Maintaining a consistent and uniform winding tension is essential to preventing an uneven distribution of turns and protecting against abnormalities in performance. Proper insulation between layers and the primary-secondary coils is equally vital, maintaining dependable functioning by averting short circuits. Sustaining good electrical performance is contingent upon both ensuring the structural integrity of the transformer and putting in place appropriate insulation measures and winding uniformity. The transformer's durability and dependability in a range of audio applications are enhanced by this meticulous attention to winding and insulation.

- Wire gauge and material choice have a significant influence on audio output transformer performance. Selecting the appropriate wire gauge is essential to guarantee that it can manage anticipated currents while reducing resistive losses. Equally important are material factors; copper is a popular material due to its high conductivity. Alternatives such as silver or other high-conductivity materials might be taken into consideration for high-end applications in order to improve electrical performance even further. The transformer's efficiency, conductivity, and general capacity to accurately reproduce audio signals are enhanced by the deliberate pairing of the right wire gauge and material with the particular requirements of the audio system.

Impedance matching

When designing an audio output transformer, impedance matching is crucial as it allows power to be transferred from the amplifier to the load as efficiently as possible. A proper impedance ratio and load matching are essential for maximizing power transmission, reducing signal distortion, preserving the audio signal's integrity, and ultimately improving the amplifier system's overall audio output quality and clarity.

- The primary-to-secondary turns ratio in audio output transformer design is a crucial factor in establishing the impedance characteristics. This ratio directly affects the impedance ratio, thus it's important to choose carefully based on the amplifier and speaker impedance requirements. To get the best fit, the transformer must be carefully built to reflect the intended load impedance back to the amplifier. To maximize quality, reduce signal distortion, and transmit power efficiently, load impedance reflection is essential. The transformer's capacity to work in perfect harmony with the amplifier and speaker—and hence maximize the performance of the entire audio system—is greatly enhanced by careful attention to the turns ratio and impedance matching.

- Load matching is pivotal in audio output transformer design, especially when it comes to speaker impedance. For effective power transmission, the impedance of the transformer must be properly matched to the nominal impedance of the speaker. This alignment reduces signal distortion and guarantees peak performance. Some transformers include multi-tap windings on the secondary side to increase flexibility. Users may choose alternative taps that match different speaker impedances thanks to this design feature, which gives them flexibility in how the transformer can be configured. Accurate speaker impedance matching and multi-tap windings provide flexibility, which makes the transformer a flexible part for audio systems with different speaker arrangements.

In the delicate domain of audio output transformer design, constructing high-quality transformers involves a comprehensive grasp of core materials, winding procedures, and impedance matching. When these design concepts are carefully taken into account, engineers and amateurs may create transformers that are exceptionally well-performing and reproducing audio signals with unmatched clarity and precision. The choice of core material lays the foundation for efficiency, winding techniques ensure the seamless transfer of signals, and impedance matching determines the effectiveness of power transfer.

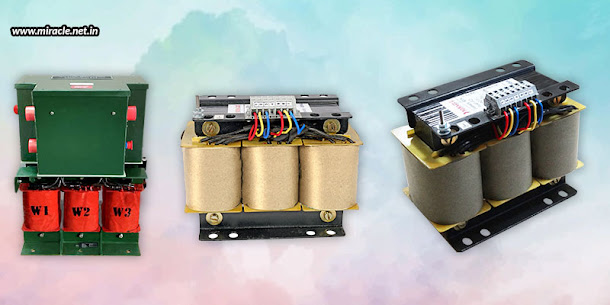

As an exemplary manufacturer in this domain, Miracle Electronics stands out as a leading provider of audio output transformers. Their dedication to excellence, expertise in transformer design, and observance of strict production guidelines establish them as a reliable collaborator for individuals in search of superior audio components. Miracle Electronics is committed to quality, and helps make high-end audio systems a reality by offering audio output transformer India that can withstand the harsh requirements of both professionals and audiophiles.