Printed Circuit Boards (or PCBs) are seen in almost every electronic device – that small green board with tiny black and golden components and connections. These tiny boards are capable of supplying electrical signals by connecting all the mounted electronic components together.

There are a variety of PCBs available in the market, which can be selected depending upon the application it needs to be used in, and the purpose it needs to serve. Some of the most common PCBs seen are single-sided, double-sided , through-hole, and surface-mount. Let’s take a look at the types of PCBs and their applications below.

Types of PCBs

Single-sided PCBs

A single-sided PCB is the most basic type, which consists of

a flat sheet of insulating material and a layer of copper foil laminated to the

substrate. The copper is etched to divide it into separate conducting lines

called traces. Then, there are all sorts of connections and electromagnetic

shielding made possible with the help of insulated wires. The copper layer is finally

coated to reduce the chances of shorts and prevent it from corrosion.

Double-sided PCBs

These PCBs are just like single-sided boards, but with

copper layers and componentson both sides of the substrate layer ,

which allows the traces to cross over each other. This results in high-density

complex circuits that are more difficult to produce. Double-sided PCBs can have

their components connected using two technologies – through hole and surface

mount. But, both these technologies come with their own benefits and

limitations.

Through-hole PCBs

This is the most basic technology that has been used since

initial times to produce PCBs, wherein the electronic components are mounted by

leads inserted through holes on one side of the board, and soldered onto the

copper traces on the other side. The leads are bent at 90 degrees to

horizontally install the through-hole parts with two axial leads, inserted into

the board, soldered, and trimmed off at the ends. The through-hole technology

requires many holes to be drilled, limiting the available routing area for

signal traces.

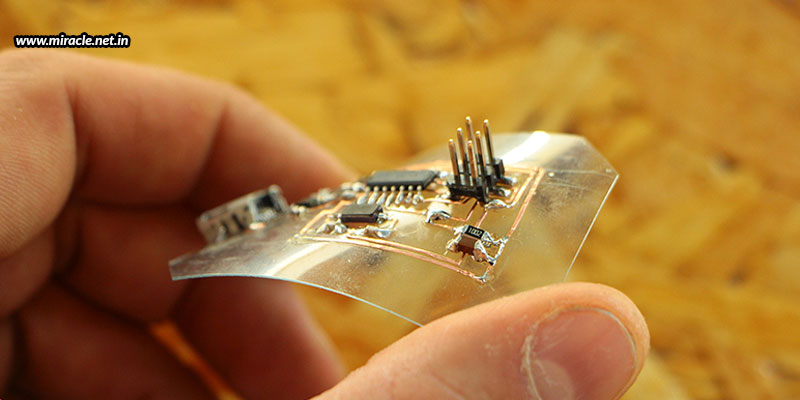

Surface-mount PCBs

Surface-mount technology came after the through-hole technology to enable mounting of very small-sized

components on the board, with small metal tabs or end caps that can be soldered

directly onto the PCB surface, instead of wire leads passing through holes.

With this technology, it became possible to mount components on both sides of

the board easily; thus allowing very small PCB assemblies with much higher

circuit densities. The technology is also automated, which reduces time and

costs related to manual labour, thus increasing production rates.

Applications of PCBs

Electronic devices – PCBs are highly used in

electronic devices, providing channels and pathways for electricity and signals

to follow, thus allowing functioning of the device.

Computers – PCBs are very popularly seen in

motherboards of computers, which makes complex functions possible too.

Medical devices – PCBs can help in the medical

industry by performing a variety of functions like diagnosing, monitoring, and

treatment. For instance, PCBs are used in the medical field in equipment like medical

imaging systems, monitors, and infusion pumps. However, the PCBs to be used in

medical devices should strictly comply to stringent standards for sanitation

and functionality.

Automotive components – Automotive components need to

withstand extreme temperatures and vibrations; and with the advancement of

technologies, PCBs are not limited to windshield wipers and headlight switches

only; rather they are also used in many other automotive components like control

systems, stereo systems, navigation systems, and sensors.

Aerospace and military components – PCBs are also

used in the most critical applications like aerospace and military. In the

aerospace industry, PCBs are used in planes, satellites, space shuttles, and

radio communication systems. And, in the military industry, PCBs are used in

communication equipment, control systems in military vehicles, firearms, and

more.

No matter what the application, you can always get the most

appropriate PCB assembly for your equipment. And, when you’re looking for

perfect products, you can always opt for Miracle Electronics’ customized

solutions to get seamless PCB assembly manufacturing from India.