The transformer is an essential component in supplying electrical power for everyday needs. These amazing machines support the entire electrical power sector by facilitating the effective transmission and distribution of electricity to buildings, commercial buildings, and industrial facilities. Yet, these heroes frequently go unseen! But here, in this blog, we’ll shed some light on these amazing equipment, giving them the respect they ought to receive!

Transformers facilitate power generation

Transformers are crucial for integrating power plants with the electrical grid, and converting generated electricity to appropriate voltage levels for distribution. They also integrate renewable energy sources like solar and wind power into the grid, and enable the generation of sustainable energy.

Transformers provide for effective power distribution

Transformers make it easier to change electrical voltage levels, enabling electricity to be delivered across great distances with little loss. They also enable dependable power supply by stepping up the voltage for effective long-distance transmission, and stepping it down for safe distribution to end consumers.

Transformers enhance energy efficiency

By working at high voltage levels, transformers reduce power losses during transmission, thus increasing the total energy efficiency. Furthermore, distribution transformers ensure that power is delivered at the proper voltage levels, reducing waste and maximizing energy efficiency. This ultimately optimizes power utilization.

Transformers ensure reliable power supply

Transformers maintain a constant voltage level, compensating for fluctuations in the power grid and guaranteeing a steady supply of electricity to consumers. They also assist in reducing problems like voltage sags, harmonics, and power surges, which improves the quality and dependability of the electrical supply.

Transformers support industrial and commercial applications

Transformers supply the necessary energy for heavy machinery and equipment used in a variety of industries. In addition, they also help the efficient operation of commercial applications by supplying dependable electricity for lighting, heating, cooling, and other operational requirements.

Transformers promote safety and protection

Transformers provide electrical isolation, preventing humans and equipment from electric shocks and short circuits. Also, transformers integrate protection devices including fuses, circuit breakers, and surge arresters, to guard against damage from electrical faults and guarantee safety.

As you can see, transformers quietly deliver electricity to homes, offices, and industries in a safe and effective manner. It is impossible to emphasize their critical importance in voltage transformation, power generation, energy efficiency, dependability, and safety. With such an extraordinary role that transformers have played in sustaining the convenience of electricity in our daily life, they are yet often neglected. This clearly shows why we say that transformers are the unsung heroes of the electrical power industry.

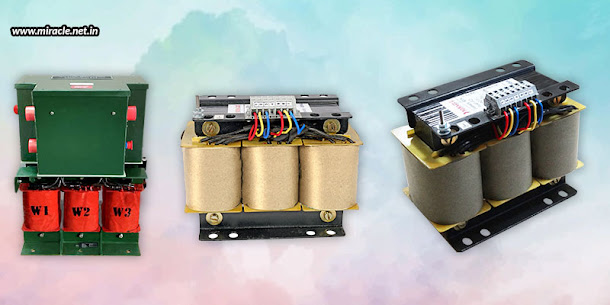

To get your hands on these silent heroes, you can get in touch with Miracle Electronics, the leading transformer manufacturer in India, who has been offering a number of different types of transformers to clients across the globe since almost three decades now! Power, toroidal, EI, three phase, SMPS, encapsulated, UI, and planar are only some of the finest transformers on the list. Choosing any of these transformers will ensure an investment in quality.

For more information, visit: https://www.miracle.net.in/