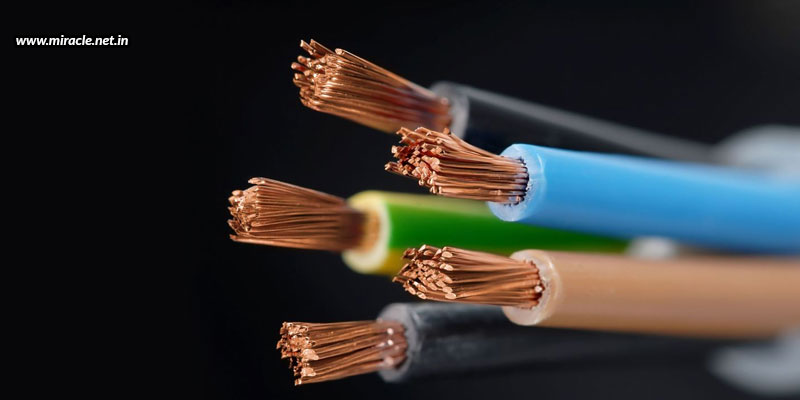

Copper wire cables are a very small part of any electronic application, but that doesn’t mean they are insignificant. In fact, they are one of the most important parts of a circuit that connects different parts and sends power or signals to them for an effective functioning. And, this is why it is highly crucial that these wires and cables are of the best quality. For this, one, you need reliable and experienced wire harness manufacturers from India, who make only genuine high-quality wires with no compromise; and two, you need thoroughly tested wire cables that ensure zero faults. Although a genuine manufacturer will himself test every product before delivering it to you, yet we put it up as a different point to bring to your notice the importance of testing.

Tests done by the manufacturer

There are a variety of different tests that are done on copper wire cables to ensure best quality and perfect functionality.

Continuity test – This test allows to check for solid wire connections within the cable. Multimeters are used to check this by measuring the current, voltage, and resistance of the circuit.

Resistance test – This test helps measure the voltage and current resistance within a cable, which can then be compared to the expected cable performance to reveal how well the cable is performing. An ohmmeter is used for this purpose, where it passes a small current through the cable and measures the voltage drop.

Isolation test – This test uses low voltage power to help see how well isolated the wires within the cable are. A megohmmeter is used to measure current leakage with a low voltage.

Shorts test – This test uses high voltage power to help find any shorts within the cable, which is not revealed when low voltage is used.

Miracle Electronics tops the list of wire harness manufacturers from India, who makes sure to conduct all the above tests and more to ensure high quality and high-performance wires and cables before delivering the same to clients.

Three tests after purchase

While your manufacturer should have done all the above-mentioned tests already, there are three other critical tests that should be done after the purchase. One is to be done during the installation, second during having it to perform the first time, and third is during frequent maintenance procedures.

During installation – You must check for any damage during transit, and ensure that the cables are working, upon installation.

When functioning first time – Once you install the cables, turn on your application and thoroughly check for any interference or problems. The cables must be compatible, and must seamlessly interact with the software and other elements involved with the application.

Frequent maintenance procedures – You must carry out maintenance procedures periodically to check if the integrity of the cables have been compromised after a set period of time, or following peak load times.

With all the above tests, you can ensure quality performance and safe procedures within the space where the application has been installed.